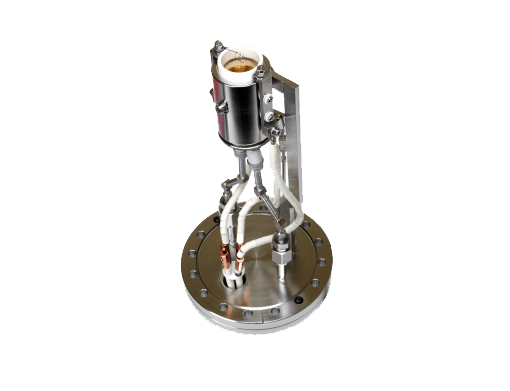

The Mini UHV 500W Gridless End-Hall Ion Source has been specially developed to provide a cost effective solution for ion assisted processes for small to medium sized UHV deposition systems. The source provides an extremely reliable and maintenance-free 500W source for many applications in PVD processes.

The compact design and rugged construction allows easy installation to both new and existing UHV vacuum deposition systems.

Features

- Available on CF flange

- Power supply now comes with touch screen interface.

- Touch Screen for allow ease of use.

- Multi-Mode system operation – Continuous, Pulse, Gas Purge, Substrate Pre-clean all at the touch of the screen.

- Save regularly used deposition procedures to file. Save up to 15 separate files with all operational parameters.

- Ion beam energies up to 225eV.

- Ion Beam power to 500 watts.

- Anode currents to 5 amps.

- Full-time use of high purity oxygen.

- Highly efficient patented gas injection design greatly reduces gas load.

- Direct water-cooling to reduce maintenance, radiation load and venting delays.

- Extremely low maintenance. The patented design utilizes a specially coated anode, that resists build-up of electrically insulating oxide coatings. No need to change anodes for different gases.

- Extremely stable operation in IAD processes due to patented electrode design.

- Broad – beam divergence for large area coverage with a uniform ion flux.

- Rapid start-up – Only 3 seconds to stable operation from Start.

- Special Coiled Filaments provide >12 hours in pure oxygen per filament.

- Pulse-mode Operation for ion-assistance of radiation-sensitive film materials such as many commonly used infrared and UV thin film materials eg MgF2 & LaF2. For further information please refer to separate information sheets.

- Gas Purge Mode provided to allow routine purging of gas lines. Automatically switches off at pre-set timeout or when gas flow reaches < 1% of flow range.

- Pre-deposition Clean Mode provided to easily pre-clean the substrates immediately prior to deposition.

- Remote Control & Monitoring of process parameters. Remote control through RS232 protocol.