EL-PRESS P-502C

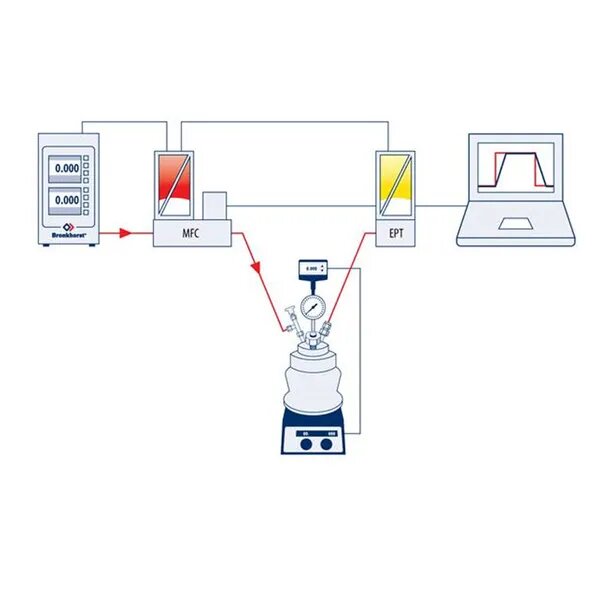

The Bronkhorst Digital Electronic Pressure Meter range are suited for precise measurement of pressure ranges between 2…100 mbar and 1,28…64 bar absolute or between 0,7…35 mbar and 1,28…64 bar gauge. These transducers (or EPT) have a well-proven compact thru-flow design and includes a diaphragm type piezo-resistive pressure sensor, a microprocessor based pc-board with signal and fieldbus conversion and a PID controller for optional pressure control by means of a separately mounted control valve

EL-PRESS series are equipped with a digital pc-board, offering high accuracy, excellent temperature stability and fast response. The main digital pc-board contains all of the general functions needed for measurement and control. In addition to the standard RS232 output the instruments also offer analog I/O. As an option, an on-board interface can be mounted to provide CANopen®, DeviceNet™, EtherCAT®, PROFIBUS DP, PROFINET, Modbus RTU, ASCII or TCP/IP, EtherNet/IP, POWERLINK or FLOW-BUS protocols.

Key features of the digital electronic pressure meter include:

- For absolute or gauge pressure

- High accuracy and repeatability

- Well proven, compact thru-flow design

- On-board PID controller for pressure control

- Analog, RS232 and fieldbus communication

How does it work?

The Bronkhorst EL-PRESS pressure sensor is a piezoresistive bridge on the surface of a silicon chip. This chip is drilled out on its reverse side, giving the inside of the chip the form of a pressure diaphragm, whose thickness determines the pressure range. When a pressure acts on this chip, the diaphragm flexes, and the resistor values of the bridge alter in proportion to the pressure. The measuring cell is separated from the external pressure by a thin, sensitive stainless steel diaphragm, and the sealed off cavity between diaphragm and cell is filled with oil.

Measurement / Control System

| Absolute pressure sensors |

|

||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Relative pressure sensors |

|

||||||||||||||||||||

| Accuracy (incl. linearity and hysteresis) | standard: ± 0,5 % FS | ||||||||||||||||||||

| Repeatability | < 0,1 % RD | ||||||||||||||||||||

| Pressure rangeability | 1:50 for pressure meter; 1 : 20 for P2-control; 1 : 5 for P1-control |

||||||||||||||||||||

| Response time (sensor) | 2 msec | ||||||||||||||||||||

| Operating temperature | -10 … +70 °C | ||||||||||||||||||||

| Temperature sensitivity | 0,1% FS/°C | ||||||||||||||||||||

| Leak integrity, outboard | tested < 2 x 10-9 mbar l/s He | ||||||||||||||||||||

| Attitude sensitivity | max. error at 90° off horizontal < 0,3 mbar | ||||||||||||||||||||

| Warm-up time | negligible |

Mechanical Parts

| Material (wetted parts) | stainless steel 316L or comparable |

|---|---|

| Process connections | compression type or face seal (VCR/VCO) couplings |

| Seals | standard: Viton®; options: EPDM, Kalrez® (FFKM), FDA and USP Class VI approved compounds |

| Weight | 0,4 kg |

| Ingress protection | IP40 |

Electrical Properties

| Power supply | +15 … 24 Vdc | ||||

|---|---|---|---|---|---|

| Max. power consumption meter |

|

||||

| Max. Power consumption controller |

|

||||

| Analog output | 0…5 (10) Vdc or 0 (4)…20 mA (sourcing output) | ||||

| Digital communication | standard: RS232; options: CANopen®, DeviceNet™, EtherCAT®, PROFIBUS DP, PROFINET, Modbus RTU, ASCII or TCP/IP, EtherNet/IP, POWERLINK or FLOW-BUS |

Electrical Connection

| Analog/RS232 | 9-pin D-connector (male); |

|---|---|

| PROFIBUS DP | bus: 9-pin D-connector (female); power: 9-pin D-connector (male); |

| CANopen® / DeviceNet™ | 5-pin M12-connector (male); |

| FLOW-BUS/Modbus-RTU/ASCII | RJ45 modular jack |

| Modbus TCP / EtherNet/IP / POWERLINK | 2 x RJ45 modular jack (in/out); |

| EtherCAT®/ PROFINET | 2 x RJ45 modular jack (in/out); |

Please Note:

The measuring cell of the pressure sensor is separated from the external pressure by a thin, sensitive stainless steel diaphragm, and the sealed off cavity between diaphragm and cell is filled with oil. Since the standard oil filling is flammable, Bronkhorst advises to take precautions when oxygen or any other explosive fluid is used.