| Plasma-Therm has pioneered dry etching for the highly specialized photomask market for more than 15 years. Mask Etcher® systems set dry etch performance and flexibility standards for photomask production. Plasma-Therm’s Mask Etcher® solution is a key enabler of Moore’s law and shrinking technology nodes.

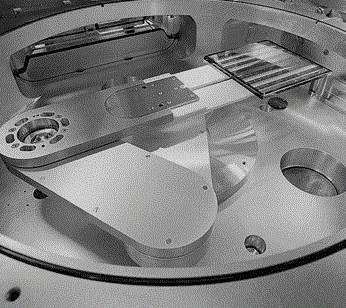

A wide variety of films can be etched from entry level 250um technology to < 32nm production with ICP high density plasma etch systems. Excellent uniformity and particle control are achieved through innovative technologies while maintaining high system production uptime. Plasma-Therm’s latest Generation V Mask Etcher excels in CD uniformity and linearity well below 5 nm. Mask Etcher 2-V Evolution |

|||||||||||

|

|||||||||||

Hardware

EndpointIntegrated multifunctional endpoint capability with EndpointWorks

Software

Process

|

Why Choose Eden Lab

Australian Company

Top Support

Full Spectrum of Products

Years of Experience

Fast Shipping

Ready to Ship Freeze Dryers

Top Support

Local Dedicated Support

Peace of Mind

Covered By Australian Law