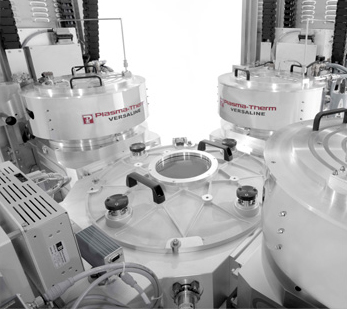

Plasma-Therm’s VERSALINE ICP is the product resulting from decades of technological evolution. Well-known and accepted product lines including the 790, Shuttlelock, and Versalock all played a role in the development of the VERSALINE ICP.

Hardware

- Flexible and upgradeable handling

– LL — single substrate or batch carrier loader

– CX — cassette-to-cassette loading of wafers or carriers - Loading configurations for single and multiple wafers

- 2 MHz ICP RF for efficient coupling of power to the plasma

- ICP source with temperature control capable of high power

- Substrate temperature control via mechanical clamp or ESC

- Efficient thermal management with monoblock electrode construction and an active backside helium circuit

- Flexible substrate bias options with 13.56 MHz and 40MHz

- Improved preventative maintenance cycles with thermally managed chamber liner and pump train

- Digital MFCs with filtered and bypassed gas lines

- Available substrate electrode temperature ranges –40ºC to 180ºC

- Chambers with corrosion-resistant surfaces

- Mag-Lev turbo pump

- Bulkhead or ballroom installation

Endpoint options

Integrated multifunctional endpoint capability with EndpointWorks®:

- Laser interferometry

- Optical emission spectroscopy (OES)

- Optical emission interferemetry (OEI)

- System parameters (throttle valve position, pressure, forward power, etc.)

- Custom inputs such as RGA and ellipsometer

Control system

Cortex® control system provides a user-friendly control interface designed for efficiency and productivity. Cortex benefits include:

- Graphical, touchscreen compatible, SEMI-standard (E-95) interface

- Comprehensive process parameter charting (real-time and post-processing)

- Automated clean and prep (ACAP) routines with configurable triggers, including RF-on time, job count, and wafer count

- Real-time process data display

- Factory automation host interface (with optional SECS/GEM license)

- Integrated recipe editor with step and tabular views

- Per-user access control for menus, screens, commands and recipes

- Auto logging of alarms, jobs, calibration, and resource usage

- Integrated with GLANCE data logging and visualization tool

Process

- Optimized etch rates

- High uniformity

- Low particulates

- Tunable selectivity

- Multilayer etch detection

- Profile control

- Large library of processes for electronic, photonic, MEMS, and nanotechnology applications (material specs available upon request)

- II-VIs and III-Vs: e.g. GaAs, InP, GaN, AlN, CdTe, InSb

- Silicon based: e.g. Si, Ge, SiGe, poly-Si, SiC, SiO2, SiNx, quartz

- Polymers: e.g. PR, PI, BCB

- Metals: e.g. Al, Cr, V, W, Mo, Ti, Ta, Nb, Cu, Au, Pt

- Metal oxides and nitrides: e.g. TiN, TaN, TiOx, TaOx

- Piezoelectrics: e.g. LiNbO3, LiTaO3

- Corrosive chemistry (e.g. HBr, Cl2, BCl3) supported with “armored” internal component