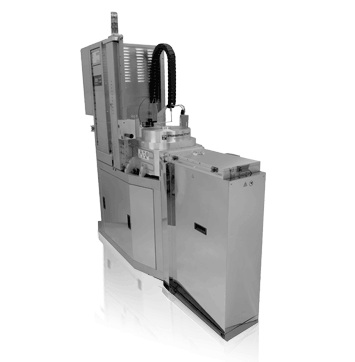

[vc_row][vc_column][vc_column_text]Plasma-Therm’s VERSALINE RIE systems are installed in a wide range of production capacity facilities – from R&D through high-volume production. VERSALINE RIE offers low maintenance and high versatility for multiple applications.

Substrate sizes are conveniently accommodated without ever needing hardware reconfiguration. For future upgradeability to ICP, a high conductance option is available.

Hardware

- Simple, low-maintenance design

– Flexible substrate bias options with 13.56 MHz and 40 MHz - Flexible and upgradeable handling

– ML — direct manual loading (single or multi-substrate)

– LL — single substrate or multi-substrate carrier loader

– CX — cassette-to-cassette loading of wafers or carriers - Improved preventative maintenance cycles with thermally managed chamber liner and pump train

- Digital MFCs with filtered and bypassed gas lines

- Mag-Lev turbo pump

- Efficient thermal management with monoblock electrode construction

- Available substrate electrode temperature ranges –40ºC to 180ºC

- Process specific electrode material

Endpoint

Integrated multifunctional endpoint capability with EndpointWorks

Laser Interferometry

- OEI

- OES

- System Parameters

- Custom inputs (e.g., RGA)

Software

- User-friendly SEMI standard interface (E-95)

- Comprehensive data logging

- Automated cleaning program (AMS)

- Real-time process data display

- Fully integrated endpoint system

- Factory automation compatible (SECS/GEM)

- Edit recipes during runs

- Multiple user access levels

- Alarm history

Process

- Tunable selectivity

- Extensive process library

- Wide process latitude

[/vc_column_text][/vc_column][/vc_row]